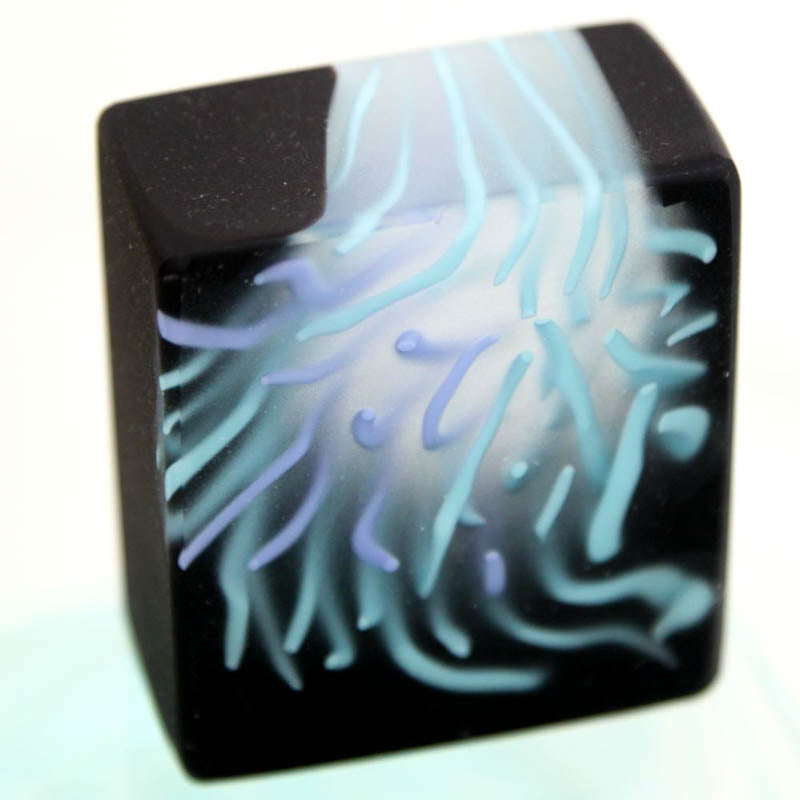

The history of Murano glass paperweights started, incredibly, thousands of years ago. It seems that paperweights were born almost by accident: at the end of the day, the glassworkers of the furnace instead of throwing away scraps of coloured glass, decided to join them in bulk in the molten glass. The result was a rounded and heavy object, useful to keep sheets of paper still.

Around 1600 B.C. Egyptians combined coloured rods, canes, and beads of glass assembled into patterns inlaid into a transparent glass shell.

Those elements were used to decorate vessels and tiles. After Egypt and its refined culture was absorbed by the Roman Empire, this kind of decorations became popular in Rome. Following the decline of the Western Empire, glass making continued to flourish and develop - again - in Egypt and Syria, now under Arab rule, and in the Eastern Empire from where it was imported into Venice and Murano, around 1200 a.D.

We have to wait 1845 to see the first examples of Murano glass paperweights. Thanks to ancient techniques and motives, in this year the glassmaker Pietro Bigaglia produced the earliest millefiori paperweight, using the best murrinas available at that time - those made by Giovanni and his son Giacomo Franchin.

Few years later, glass paperweights were produced in France, Germany and the UK.

Since 1860, however, the popularity of Murano glass paperweights decreased in favour of the French models. Soon in Murano the production stopped.

It will be resumed in 1930 and at that time it was divided into two great categories: a merely commercial one, with repetitive motives and designs, of little or none aesthetic nor artistic value; the other one carried on by the most importat names of Murano glassmaking such as Barbini , Venini , Salviati , Cenedese , Vistosi , in which experimentation with new aesthetic languages was fundamental and where production was limited to a few examples.

Most of them are created by making a gather and pressing it vertically onto millefiori cane or coloured glass pieces, shaping these as necessary and then covering the whole with a further gather of clear glass. This is then blocked into a spherical shape and cracked off into an annealing kiln. Bubbles can be introduced by simply poking a spike into the first gather. Though it sounds simple, a complicated millefiori paperweight could take up to a day to be completed and up to 180-220 canes.

That’s the reason why - starting from 1970 - the production saw a new contraction and has been gradually moved to the mainland around Venice, whereas a niche production of top of range and refined paperweights has remained on the island.

This was due in order to remain competitive and fight the invasion of false paperweights marked as "Murano glass" but - in reality - made in China.

When they appeared, paperweights were a functional form of glass, completely new and modern, but that was based on the ancient techniques of millefiori glass and lampwork thechinques. The goal, keeping papers still on the desk, has always been of secondary importance because their main feature has always been the artistic and decorative value.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.